NSN 5306-01-365-0363 MB1544D15, MB154-4D15, AIC6874D15

Product Details | CLOSE TOLERANCE BOLT

5306-01-365-0363 An externally threaded fastener whose unthreaded portion is of a specified grip length, plated or unplated, and is machined to a tolerance of one thousandth (0.001) of an inch (0.025 mm) or less of a specific diameter for items one inch (25 mm) or less in diameter. Items over one inch (25 mm) in diameter shall have a tolerance of fifteen ten-thousandths (0.0015) of an inch (0.038 mm) or less. The nominal major diameter of the threads shall be at least one thousandth (0.001) of an inch (0.025 mm) below the minimum shank diameter, but not below the minimum major diameter for applicable class of fit, as shown in the Screw Thread Standards, FED STD H28 and/or other nationally recognized standards. The head is not designed to be held or driven with an inserted driver, nor is it designed for rotation by the thumb and fingers. A locking feature may be incorporated in the design of the head or threads. For items having close tolerance, and fabricated from material having 160,000 pounds per square inch (1100 megapascals) minimum tensile strength, see BOLT, SHEAR. For items fabricated from material having less than 160,000 pounds per square inch (1100 megapascals) minimum tensile strength and not having a close tolerance, see BOLT, MACHINE.

Part Alternates: MB1544D15, MB154-4D15, AIC6874D15, AIC687-4D15, S4064D15, S406-4D15, ST3M7444D15, ST3M744-4D15, VCG00014D15, VCG0001-4D15, VS31744D15, VS3174-4D15, PBF12654D15, PBF1265-4D15, 11823-4D15 , 1228954D15, 122895-4D15, 5306-01-365-0363, 01-365-0363, 5306013650363, 118234D15, 013650363

Hardware and Abrasives | Bolts

| Supply Group (FSG) | NSN Assign. | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 53 | 30 SEP 1992 | 01-365-0363 | 27851 ( BOLT, CLOSE TOLERANCE ) |

Demand History | NSN 5306-01-365-0363

| Part Number | Request Date | QTY | Origin |

|---|---|---|---|

| 11823-4D15 | 2021-06-159 | 51 | DIBBS |

| 122895-4D15 | 2021-06-159 | 51 | DIBBS |

| AIC687-4D15 | 2021-06-159 | 51 | DIBBS |

| GS1015-4D15 | 2021-06-159 | 51 | DIBBS |

| MB154-4D15 | 2021-06-159 | 51 | DIBBS |

| PBF1265-4D15 | 2021-06-159 | 51 | DIBBS |

| S406-4D15 | 2021-06-159 | 51 | DIBBS |

| ST3M744-4D15 | 2021-06-159 | 51 | DIBBS |

| VCG0001-4D15 | 2021-06-159 | 51 | DIBBS |

| VS3174-4D15 | 2021-06-159 | 51 | DIBBS |

| 11823-4D15 | 2020-11-317 | 16 | DIBBS |

| 122895-4D15 | 2020-11-317 | 16 | DIBBS |

| AIC687-4D15 | 2020-11-317 | 16 | DIBBS |

| GS1015-4D15 | 2020-11-317 | 16 | DIBBS |

| MB154-4D15 | 2020-11-317 | 16 | DIBBS |

| PBF1265-4D15 | 2020-11-317 | 16 | DIBBS |

| S406-4D15 | 2020-11-317 | 16 | DIBBS |

| ST3M744-4D15 | 2020-11-317 | 16 | DIBBS |

| VCG0001-4D15 | 2020-11-317 | 16 | DIBBS |

| VS3174-4D15 | 2020-11-317 | 16 | DIBBS |

| 11823-4D15 | 2020-09-274 | 11 | DIBBS |

| 122895-4D15 | 2020-09-274 | 11 | DIBBS |

| AIC687-4D15 | 2020-09-274 | 11 | DIBBS |

| GS1015-4D15 | 2020-09-274 | 11 | DIBBS |

| MB154-4D15 | 2020-09-274 | 11 | DIBBS |

| PBF1265-4D15 | 2020-09-274 | 11 | DIBBS |

| S406-4D15 | 2020-09-274 | 11 | DIBBS |

| ST3M744-4D15 | 2020-09-274 | 11 | DIBBS |

| VCG0001-4D15 | 2020-09-274 | 11 | DIBBS |

| VS3174-4D15 | 2020-09-274 | 11 | DIBBS |

| 11823-4D15 | 2020-05-124 | 9 | DIBBS |

| 122895-4D15 | 2020-05-124 | 9 | DIBBS |

| AIC687-4D15 | 2020-05-124 | 9 | DIBBS |

| GS1015-4D15 | 2020-05-124 | 9 | DIBBS |

| MB154-4D15 | 2020-05-124 | 9 | DIBBS |

| PBF1265-4D15 | 2020-05-124 | 9 | DIBBS |

| S406-4D15 | 2020-05-124 | 9 | DIBBS |

| ST3M744-4D15 | 2020-05-124 | 9 | DIBBS |

| VCG0001-4D15 | 2020-05-124 | 9 | DIBBS |

| VS3174-4D15 | 2020-05-124 | 9 | DIBBS |

| 11823-4D15 | 2020-01-05 | 6 | DIBBS |

| 122895-4D15 | 2020-01-05 | 6 | DIBBS |

| AIC687-4D15 | 2020-01-05 | 6 | DIBBS |

| GS1015-4D15 | 2020-01-05 | 6 | DIBBS |

| MB154-4D15 | 2020-01-05 | 6 | DIBBS |

| PBF1265-4D15 | 2020-01-05 | 6 | DIBBS |

| S406-4D15 | 2020-01-05 | 6 | DIBBS |

| ST3M744-4D15 | 2020-01-05 | 6 | DIBBS |

| VCG0001-4D15 | 2020-01-05 | 6 | DIBBS |

| VS3174-4D15 | 2020-01-05 | 6 | DIBBS |

| 11823-4D15 | 2019-08-217 | 5 | DIBBS |

| 122895-4D15 | 2019-08-217 | 5 | DIBBS |

| AIC687-4D15 | 2019-08-217 | 5 | DIBBS |

| GS1015-4D15 | 2019-08-217 | 5 | DIBBS |

| MB154-4D15 | 2019-08-217 | 5 | DIBBS |

| PBF1265-4D15 | 2019-08-217 | 5 | DIBBS |

| S406-4D15 | 2019-08-217 | 5 | DIBBS |

| ST3M744-4D15 | 2019-08-217 | 5 | DIBBS |

| VCG0001-4D15 | 2019-08-217 | 5 | DIBBS |

| VS3174-4D15 | 2019-08-217 | 5 | DIBBS |

| 5306-01-365-0363 | 2014-11-313 | 16 | DIBBS |

| 5306-01-365-0363 | 2014-06-161 | 15 | DIBBS |

| 5306-01-365-0363 | 2012-02-46 | 28 | DIBBS |

| 5306-01-365-0363 | 2011-12-342 | 7 | DIBBS |

| 5306-01-365-0363 | 2011-11-305 | 6 | DIBBS |

Cross Reference | NSN 5306-01-365-0363

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| 11823-4D15 | 59563 | REID PRODUCTS INC. DBA REID PRODUCTS |

| 122895-4D15 | 80539 | SPS TECHNOLOGIES, LLC DBA AEROSPACE FASTENERS GROUP |

| AIC687-4D15 | 06725 | SPS TECHNOLOGIES LLC DBA AIR INDUSTRIES |

| MB154-4D15 | 73197 | HI-SHEAR CORPORATION |

| MB154-4D15 | L4528 | LISI AEROSPACE CANADA CORP |

| PBF1265-4D15 | 27624 | SPS TECHNOLOGIES, LLC DBA PB FASTENERS |

| S406-4D15 | 17446 | HUCK INTERNATIONAL, INC. DBA ALCOA FASTENING SYSTEMS |

| S406-4D15 | 97928 | HUCK INTL INC |

| ST3M744-4D15 | 0PTK6 | SPS TECHNOLOGIES INC |

| ST3M744-4D15 | 0ZC92 | HEARTLAND PRECISION FASTENERS, INC. |

| ST3M744-4D15 | 58998 | EMHART TEKNOLOGIES LLC DBA FASTENER INNOVATION TECHNOLOGY |

| ST3M744-4D15 | 76301 | BOEING COMPANY, THE DBA BOEING |

| VCG0001-4D15 | 06710 | VALLEY-TODECO, INC. |

| VS3174-4D15 | 06950 | ALCOA GLOBAL FASTENERS, INC. DBA ALCOA FASTENING SYSTEMS |

| VS3174-4D15 | 92215 | ALCOA GLOBAL FASTENERS, INC. DBA ALCOA FASTENING SYSTEMS |

Request a Quote

What Our Customers Say

Compare

Related Products | NSN 5306-01-365-0363

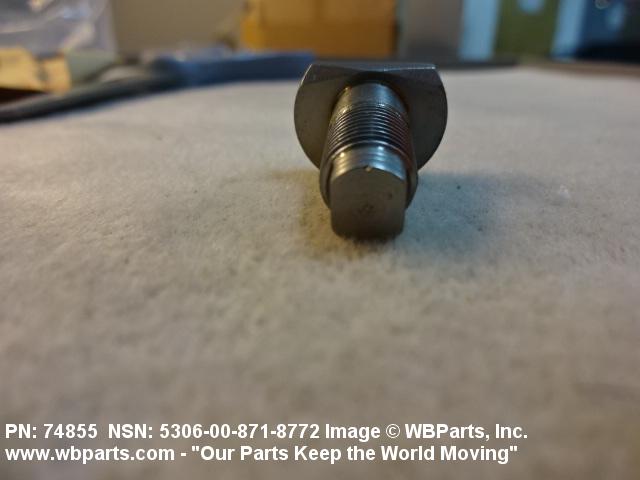

Technical Data | NSN 5306-01-365-0363

| Characteristic | Specifications |

|---|---|

| THREAD SERIES DESIGNATOR | UNJF |

| NOMINAL THREAD DIAMETER | 0.250 INCHES |

| THREAD QUANTITY PER INCH | 28 |

| THREAD CLASS | 3A |

| THREAD DIRECTION | RIGHT-HAND |

| THREAD LENGTH | 0.316 INCHES NOMINAL |

| FASTENER LENGTH | 1.244 INCHES MINIMUM AND 1.264 INCHES MAXIMUM |

| MATERIAL | STEEL COMP XM-13 OVERALL |

| MATERIAL DOCUMENT AND CLASSIFICATION | AMS5629 ASSN STD SINGLE MATERIAL RESPONSE OVERALL |

| SURFACE TREATMENT | PASSIVATE OVERALL |

| SURFACE TREATMENT DOCUMENT AND CLASSIFICATION | QQ-P-35 FED SPEC SINGLE TREATMENT RESPONSE OVERALL |

| MINIMUM TENSILE STRENGTH | 125000 POUNDS PER SQUARE INCH |

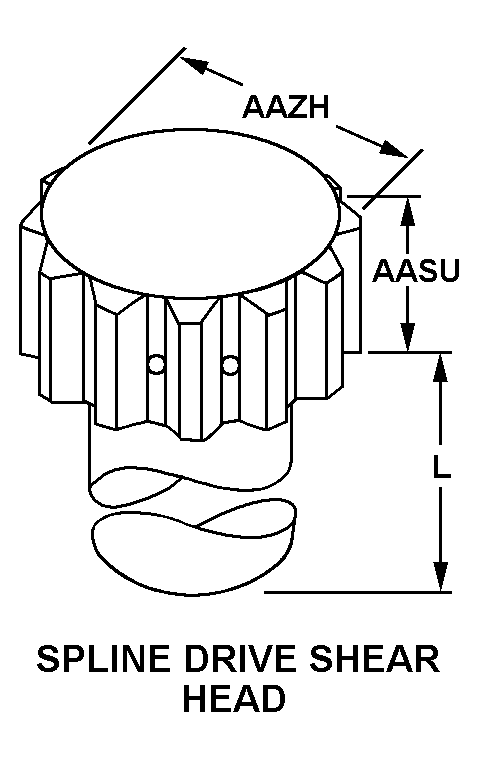

| HEAD STYLE | C12 SPLINE DRIVE SHEAR HEAD |

| HEAD HEIGHT | 0.164 INCHES NOMINAL |

| HEAD MINOR DIAMETER | 0.448 INCHES MINIMUM AND 0.455 INCHES MAXIMUM |

| GRIP LENGTH | 0.928 INCHES MINIMUM AND 0.948 INCHES MAXIMUM |

| GRIP DIAMETER | 0.2490 INCHES MINIMUM AND 0.2495 INCHES MAXIMUM |

| DISTANCE FROM HEAD LARGEST BEARING SURFACE TO SHANK HOLE CENTER | 1.126 INCHES MINIMUM AND 1.156 INCHES MAXIMUM FIRST HOLE |

| SHANK UNTHREADED HOLE DIAMETER | 0.076 INCHES MINIMUM AND 0.081 INCHES MAXIMUM FIRST HOLE |

Restrictions/Controls & Freight Information | NSN 5306-01-365-0363

| Category | Code | Description |

|---|---|---|

| Shelf-Life Code: | 0 | Nondeteriorative |

| Hazardous Material Indicator Code | N | There is no data in the HMIS and the NSN is in an FSC not generally suspected of containing hazardous materials |

| Demilitarization Code: | A | Non-Munitions List Item/ Non-Strategic List Item - Demilitarization not required. |

| Controlled Inventory Item Code: | U | UNCLASSIFIED |

| Precious Metals Indicator Code: | A | Item does not contain precious metal |

| Criticality Code: | X | The item does not have a nuclear hardened feature or any other critical feature such as tolerance, fit restriction or application. |

| Automatic Data Processing Equipment: | 0 | Represents items with no ADP components. NOTE: Codes 1 through 6 are only to be used when the item is Automatic Data Processing Equipment (ADPE) in its entirety and is limited to the type meeting only one of the definitions for codes 1 through 6. (See code 9) |

| Category | Code | Description |

|---|---|---|

| NMF Description | 093486 | BOLTS,NUTS OR SCREWS, NOI (SUB 3) |

| Less than car load rating | ||

| Less than truck load rating | W | Rating Variable |

| Water commodity Code | 573 | unknown |

| Originating Activity Code | KZ | Defense Supply Center Philadelphia Philadelphia, PA 19101 |

| Air Dimension Code | A | Shipment is not a consolidation and does not exceed 72 inches in any dimension. |

| Air Commodity | B | Construction materials: Includes paint and related materials, prefabricated building, wood products, metal and composition materials and their products, commercial hardware and miscellaneous items, cement, asphalt, building maintenance materials. |

| Air Special Handling | Z | No special handling required. |

| Special Handling Code | 9 | unknonwn |

| HAZMAT | ||

| Type of Cargo | Z | No special type of cargo code applicable |

Management | NSN 5306-01-365-0363

| Category | Code | Description |

|---|---|---|

| Cognizance Codes | 9B | Navy-owned stocks of DLA material Naval Inventory Control Point, Mechanicsburg |

| Source of Supply | SMS | Defense Logistics Agency Enterprise Business Systems |

| Agency | DN | Department of the Navy |

| Service Organization | N | U.S. Navy |

| Acquisition Advice Codes | Z | INSURANCE/NUMERIC STOCKAGE OBJECTIVE ITEM # Items which may be required occasionally or intermittently, and prudence requires that a nominal quantity of materiel be stocked due to the essentiality or the lead time of the item. 1. The item is centrally managed, stocked, and issued. 2. Requisitions will be submitted in accordance with IMM/Service requisitioning procedures. |

| Controlled Item Code | U | UNCLASSIFIED |

| Shelf Life Code | 0 | Nondeteriorative |

| Purchasing | QTY UOM |

1 EA : Each |