NSN 5305-01-053-3360 AIC984513, AIC984-5-13, AIC984513P

Product Details | CLOSE TOLERANCE SCREW

5305-01-053-3360 A SCREW, MACHINE or SCREW, CAP, SOCKET HEAD whose unthreaded portion is of specified grip length, plated or unplated, and is machined to a tolerance of one thousandth (0.001 IN.) (0.025 mm) or less of a specific diameter for items (1.000 IN.) (25 mm) or less in diameter. Items over (1.000 IN.) (25 mm) in diameter shall have a tolerance of fifteen ten thousandths (0.0015 IN.) (0.038 mm) or less. The nominal major diameter of the threads shall be at least one thousandth (0.001 IN.) (0.025 mm) below the minimum shank diameter, but not below the minimum major diameter for applicable class of fit, as shown in the Screw Thread Standards, FED STD H28 and/or other nationally recognized standards. The head is designed to be held or driven with an inserted driver. It is not designed for rotation by the thumb and fingers. A locking feature may be incorporated in the design of the head or threads.

Part Alternates: AIC984513, AIC984-5-13, AIC984513P, AIC984-5-13P, C7984513, C7984-5-13, C7984513P, C7984-5-13P, C984513, C984-5-13, H044513, H044-5-13, PBF1165513P, PBF1165-5-13P, VT1693513P, VT1693-5-13P, 1215575A13P, 121557-5-A13P, 5305-01-053-3360, 01-053-3360, 5305010533360, 010533360

Hardware and Abrasives | Screws

| Supply Group (FSG) | NSN Assign. | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 53 | 02 JAN 1978 | 01-053-3360 | 29294 ( SCREW, CLOSE TOLERANCE ) |

Demand History | NSN 5305-01-053-3360

| Part Number | Request Date | QTY | Origin |

|---|---|---|---|

| 5305-01-053-3360 | 2020-06-157 | 1 | DIBBS-RFPs |

| 121557-5-A13P | 2019-12-357 | 569 | DIBBS |

| AIC984-5-13 | 2019-12-357 | 569 | DIBBS |

| H044-5-13 | 2019-12-357 | 569 | DIBBS |

| PBF1165-5-13P | 2019-12-357 | 569 | DIBBS |

| VT1693-5-13P | 2019-12-357 | 569 | DIBBS |

| 121557-5-A13P | 2019-12-349 | 569 | DIBBS |

| AIC984-5-13 | 2019-12-349 | 569 | DIBBS |

| H044-5-13 | 2019-12-349 | 569 | DIBBS |

| PBF1165-5-13P | 2019-12-349 | 569 | DIBBS |

| VT1693-5-13P | 2019-12-349 | 569 | DIBBS |

| 121557-5-A13P | 2019-05-123 | 431 | DIBBS |

| AIC984-5-13 | 2019-05-123 | 431 | DIBBS |

| H044-5-13 | 2019-05-123 | 431 | DIBBS |

| PBF1165-5-13P | 2019-05-123 | 431 | DIBBS |

| VT1693-5-13P | 2019-05-123 | 431 | DIBBS |

| 121557-5-A13P | 2019-04-115 | 431 | DIBBS |

| AIC984-5-13 | 2019-04-115 | 431 | DIBBS |

| H044-5-13 | 2019-04-115 | 431 | DIBBS |

| PBF1165-5-13P | 2019-04-115 | 431 | DIBBS |

| VT1693-5-13P | 2019-04-115 | 431 | DIBBS |

| 5305-01-053-3360 | 2018-07-191 | 467 | DIBBS |

| 5305-01-053-3360 | 2017-06-177 | 182 | DIBBS |

| 5305-01-053-3360 | 2014-07-210 | 794 | DIBBS |

| 5305-01-053-3360 | 2010-04-120 | 780 | DIBBS |

| 1215575A13P | 2009-11-310 | 1 | United States |

| 5305-01-053-3360 | 2009-09-273 | 2116 | DIBBS |

| 5305-01-053-3360 | 2008-12-344 | 747 | DIBBS |

| 5305-01-053-3360 | 2008-03-64 | 1571 | DIBBS |

Cross Reference | NSN 5305-01-053-3360

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| 121557-5-A13P | 56878 | SPS TECHNOLOGIES, LLC DBA AEROSPACE DIVISION |

| 121557-5-A13P | 80539 | SPS TECHNOLOGIES, LLC DBA AEROSPACE FASTENERS GROUP |

| AIC984-5-13 | 06725 | SPS TECHNOLOGIES LLC DBA AIR INDUSTRIES |

| AIC984-5-13P | 06725 | SPS TECHNOLOGIES LLC DBA AIR INDUSTRIES |

| C7984-5-13 | 81755 | LOCKHEED MARTIN CORPORATION DBA LOCKHEED MARTIN AERONAUTICS |

| C7984-5-13P | 81755 | LOCKHEED MARTIN CORPORATION DBA LOCKHEED MARTIN AERONAUTICS |

| C984-5-13 | 81755 | LOCKHEED MARTIN CORPORATION DBA LOCKHEED MARTIN AERONAUTICS |

| H044-5-13 | 17446 | HUCK INTERNATIONAL, INC. DBA ALCOA FASTENING SYSTEMS |

| PBF1165-5-13P | 27624 | SPS TECHNOLOGIES, LLC DBA PB FASTENERS |

| VT1693-5-13P | 06950 | ALCOA GLOBAL FASTENERS, INC. DBA ALCOA FASTENING SYSTEMS |

| VT1693-5-13P | 17446 | HUCK INTERNATIONAL, INC. DBA ALCOA FASTENING SYSTEMS |

| VT1693-5-13P | 92215 | ALCOA GLOBAL FASTENERS, INC. DBA ALCOA FASTENING SYSTEMS |

Request a Quote

What Our Customers Say

Compare

Related Products | NSN 5305-01-053-3360

Technical Data | NSN 5305-01-053-3360

| Characteristic | Specifications |

|---|---|

| THREAD SERIES DESIGNATOR | UNF |

| NOMINAL THREAD DIAMETER | 0.312 INCHES |

| THREAD QUANTITY PER INCH | 24 |

| THREAD CLASS | 3A |

| THREAD DIRECTION | RIGHT-HAND |

| THREAD LENGTH | 0.413 INCHES MINIMUM AND 0.463 INCHES MAXIMUM |

| FASTENER LENGTH | 1.235 INCHES MINIMUM AND 1.265 INCHES MAXIMUM |

| MATERIAL | STEEL COMP H11 OVERALL |

| MATERIAL DOCUMENT AND CLASSIFICATION | AMS 6487 ASSN STD SINGLE MATERIAL RESPONSE OVERALL |

| SURFACE TREATMENT | CADMIUM OVERALL |

| SURFACE TREATMENT DOCUMENT AND CLASSIFICATION | NAS 672 ASSN STD SINGLE TREATMENT RESPONSE OVERALL |

| HARDNESS RATING | 46.0 ROCKWELL C MINIMUM AND 49.0 ROCKWELL C MAXIMUM OVERALL |

| MINIMUM TENSILE STRENGTH | 220000 POUNDS PER SQUARE INCH |

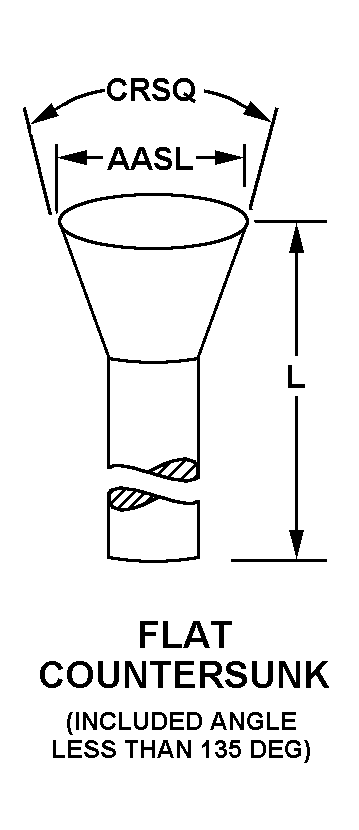

| HEAD STYLE | C50 FLAT COUNTERSUNK |

| HEAD DIAMETER | 0.573 INCHES MINIMUM AND 0.635 INCHES MAXIMUM |

| COUNTERSINK ANGLE | 99.0 DEGREES MINIMUM AND 101.0 DEGREES MAXIMUM |

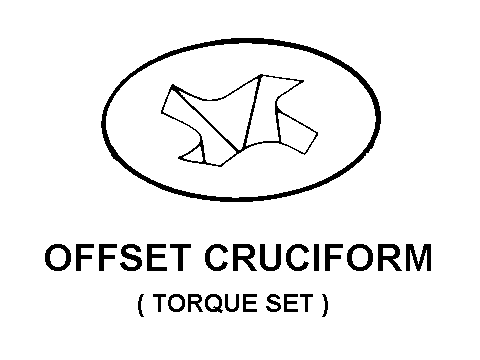

| INTERNAL DRIVE STYLE | D8 TORQUE SET |

| GRIP LENGTH | 0.802 INCHES MINIMUM AND 0.822 INCHES MAXIMUM |

| GRIP DIAMETER | 0.3110 INCHES MINIMUM AND 0.3120 INCHES MAXIMUM |

Restrictions/Controls & Freight Information | NSN 5305-01-053-3360

| Category | Code | Description |

|---|---|---|

| Shelf-Life Code: | 0 | Nondeteriorative |

| Hazardous Material Indicator Code | N | There is no data in the HMIS and the NSN is in an FSC not generally suspected of containing hazardous materials |

| Demilitarization Code: | A | Non-Munitions List Item/ Non-Strategic List Item - Demilitarization not required. |

| Controlled Inventory Item Code: | U | UNCLASSIFIED |

| Precious Metals Indicator Code: | U | Precious metal type is unknown |

| Criticality Code: | X | The item does not have a nuclear hardened feature or any other critical feature such as tolerance, fit restriction or application. |

| Category | Code | Description |

|---|---|---|

| NMF Description | 093486 | BOLTS,NUTS OR SCREWS, NOI (SUB 3) |

| Less than car load rating | ||

| Less than truck load rating | W | Rating Variable |

| Water commodity Code | 713 | unknown |

| Originating Activity Code | SU | Ogden Air Logistics Center Hill AFB, UT 84056-5609 |

| Air Dimension Code | A | Shipment is not a consolidation and does not exceed 72 inches in any dimension. |

| Air Commodity | B | Construction materials: Includes paint and related materials, prefabricated building, wood products, metal and composition materials and their products, commercial hardware and miscellaneous items, cement, asphalt, building maintenance materials. |

| Air Special Handling | Z | No special handling required. |

| Special Handling Code | 9 | unknonwn |

| HAZMAT | ||

| Type of Cargo | Z | No special type of cargo code applicable |

Management | NSN 5305-01-053-3360

| Category | Code | Description |

|---|---|---|

| Budget Code | 9 | General Support DIV57X4921.070:Air Force decentrally managed expense items (ERRC XB3, XF-3) with a unit cost of less than $250,000 that are requisitioned/procured at base (retail) level from DLA, GSA, Army, Navy, Depot Maintenance Service, Air Force Industrial Fund (AFMC), local manufacture and commercial vendors. |

| Price Validation | N | The current standard price in Catalog Management Data (CMD) has not analyzed or coded for LP/LM.

|

| Fund Code | SF | Stock fund applicable to items managed for the Air Force by the respective Inventory Control Point. |

| Materiel Management Aggregation Code | SX | SX:AF SICA RESIDUAL MMAC-OC-ALC |

| Source of Supply | SMS | Defense Logistics Agency Enterprise Business Systems |

| Agency | DF | Department of the Air Force |

| Service Organization | F | U.S. Air Force |

| Reparability | N | Stock Fund (except Munitions) |

| Acquisition Advice Codes | D | DoD INTEGRATED MATERIEL-MANAGED, STOCKED, AND ISSUED # Issue, transfer, or shipment is not subject to specialized controls other than those imposed by the Integrated Materiel Manager/Service supply policy. 1. The item is centrally managed, stocked, and issued. 2. Requisitions must contain the fund citation required to acquire the item. Requisitions will be submitted in accordance with Integrated Materiel Manager(IMM)/Service requisitioning procedures. |

| Controlled Item Code | U | UNCLASSIFIED |

| Shelf Life Code | 0 | Nondeteriorative |

| Purchasing | QTY UOM |

M EA : Each |

| Category | Code | Description |

|---|---|---|

| Cognizance Codes | 9B | Navy-owned stocks of DLA material Naval Inventory Control Point, Mechanicsburg |

| Source of Supply | SMS | Defense Logistics Agency Enterprise Business Systems |

| Agency | DN | Department of the Navy |

| Service Organization | N | U.S. Navy |

| Acquisition Advice Codes | D | DoD INTEGRATED MATERIEL-MANAGED, STOCKED, AND ISSUED # Issue, transfer, or shipment is not subject to specialized controls other than those imposed by the Integrated Materiel Manager/Service supply policy. 1. The item is centrally managed, stocked, and issued. 2. Requisitions must contain the fund citation required to acquire the item. Requisitions will be submitted in accordance with Integrated Materiel Manager(IMM)/Service requisitioning procedures. |

| Controlled Item Code | U | UNCLASSIFIED |

| Shelf Life Code | 0 | Nondeteriorative |

| Purchasing | QTY UOM |

M EA : Each |