NSN 3120-01-203-4442 ARBL461TW, ARBL4-61TW, ARL48W3

Product Details | ROD END PLAIN BEARING

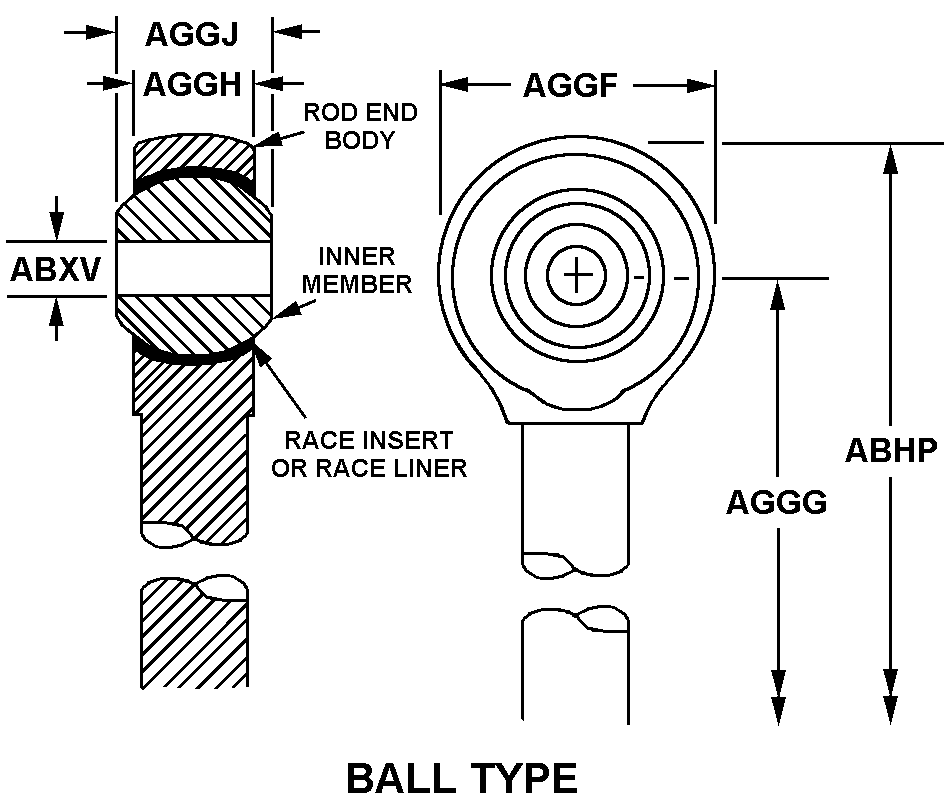

3120-01-203-4442 A detachable assembly in or on which a journal, gudgeon, pivot, or the like moves. It is used to carry a load and to reduce sliding friction. It does not employ rolling elements. The outer member of the assembly is modified to provide a shank. The inner member may be either a plain spherical bearing or a sleeve bearing. Excludes BEARING, PLAIN, SPHERICAL and BEARING, PLAIN, SELF-ALIGNING.

Part Alternates: ARBL461TW, ARBL4-61TW, ARL48W3, ARL4-8W-3, BACB10Z4LT, BRELHS42242EL1, BRELHS-4-2242-EL-1, HB4201KLT, HB4-201KLT, KBL150WT, KBL-150WT, KBL4150WT, KBL4-150WT, FSSKL4AS2, FSSKL-4AS-2, 51589L041VL, 51589L-041VL, 3120-01-203-4442, 01-203-4442, 3120012034442, 012034442

Bearings | Bearings, Plain, Unmounted

| Supply Group (FSG) | NSN Assign. | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 31 | 14 MAR 1985 | 01-203-4442 | 13209 ( BEARING, PLAIN, ROD END ) |

Demand History | NSN 3120-01-203-4442

| Part Number | Request Date | QTY | Origin |

|---|---|---|---|

| BACB10Z4LT | 2025-07-203 | 333 | DIBBS |

| BACB10Z4LT | 2025-07-195 | 333 | DIBBS |

| BACB10Z4LT | 2024-10-291 | 232 | DIBBS |

| BACB10Z4LT | 2024-10-283 | 232 | DIBBS |

| BACB10Z4LT | 2023-09-250 | 222 | DIBBS |

| BACB10Z4LT | 2021-10-278 | 458 | DIBBS |

| 3120-01-203-4442 | 2020-10-304 | 1 | DIBBS-RFPs |

| BACB10Z4LT | 2020-02-43 | 693 | DIBBS |

| 3120-01-203-4442 | 2013-11-324 | 1 | DIBBS-RFPs |

| 3120-01-203-4442 | 2013-08-240 | 908 | DIBBS |

| 3120-01-203-4442 | 2013-08-217 | 374 | DIBBS |

| 3120-01-203-4442 | 2013-01-29 | 438 | DIBBS |

| 3120-01-203-4442 | 2012-11-307 | 438 | DIBBS |

| 3120-01-203-4442 | 2012-03-85 | 195 | DIBBS |

| 3120-01-203-4442 | 2009-04-104 | 9 | DIBBS |

| 3120-01-203-4442 | 2009-02-43 | 181 | DIBBS |

| 3120-01-203-4442 | 2008-11-330 | 465 | DIBBS |

| 3120-01-203-4442 | 2008-10-302 | 135 | DIBBS |

| 3120-01-203-4442 | 2008-09-261 | 90 | DIBBS |

| HB4201KLT | 2008-01-31 | 24 | US |

Cross Reference | NSN 3120-01-203-4442

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| 51589L-041VL | 09455 | RBC TRANSPORT DYNAMICS CORP. DIV RBC TRANSPORT DYNAMICS |

| ARBL4-61TW | 15860 | NEW HAMPSHIRE BALL BEARINGS, INC. DBA ASTRO DIVISION |

| ARL4-8W-3 | 50294 | NEW HAMPSHIRE BALL BEARINGS, INC. DBA NHBB |

| BACB10Z4LT | 02758 | U S BEARINGS |

| BACB10Z4LT | 09455 | RBC TRANSPORT DYNAMICS CORP. DIV RBC TRANSPORT DYNAMICS |

| BACB10Z4LT | 15860 | NEW HAMPSHIRE BALL BEARINGS, INC. DBA ASTRO DIVISION |

| BACB10Z4LT | 16746 | SPECLINE INC. |

| BACB10Z4LT | 50294 | NEW HAMPSHIRE BALL BEARINGS, INC. DBA NHBB |

| BACB10Z4LT | 56644 | AURORA BEARING COMPANY |

| BACB10Z4LT | 73134 | ROLLER BEARING COMPANY OF AMERICA, INC. |

| BACB10Z4LT | 81205 | THE BOEING COMPANY DBA BOEING |

| BACB10Z4LT | 81376 | RBC SOUTHWEST PRODUCTS, INC. |

| BACB10Z4LT | 97613 | DOVER ENGINEERED SYSTEMS, INC. DBA KAHR BEARING |

| BRELHS-4-2242-EL-1 | 81376 | RBC SOUTHWEST PRODUCTS, INC. |

| FSSKL-4AS-2 | 73134 | ROLLER BEARING COMPANY OF AMERICA, INC. |

| HB4-201KLT | 02758 | U S BEARINGS |

| KBL-150WT | 97613 | DOVER ENGINEERED SYSTEMS, INC. DBA KAHR BEARING |

| KBL4-150WT | 97613 | DOVER ENGINEERED SYSTEMS, INC. DBA KAHR BEARING |

Request a Quote

What Our Customers Say

Compare

NSNs for Compare ( up to 4 ): Add 3120-01-203-4442

Related Products | NSN 3120-01-203-4442

Technical Data | NSN 3120-01-203-4442

| Characteristic | Specifications |

|---|---|

| MATERIAL | STEEL COMP 440C INNER MEMBER STEEL COMP XM-12 RACE INSERT STEEL COMP XM-12 ROD END BODY |

| MATERIAL DOCUMENT AND CLASSIFICATION | QQ-S-763 FED SPEC SINGLE MATERIAL RESPONSE INNER MEMBER AMS 5658 ASSN STD SINGLE MATERIAL RESPONSE OR AMS 5659 ASSN STD SINGLE MATERIAL RESPONSE RACE INSERT AMS 5658 ASSN STD SINGLE MATERIAL RESPONSE OR AMS 5659 ASSN STD SINGLE MATERIAL RESPONSE ROD END BODY |

| HARDNESS RATING | 55.0 ROCKWELL C MINIMUM AND 61.0 ROCKWELL C MAXIMUM INNER MEMBER 35.0 ROCKWELL C MINIMUM AND 44.0 ROCKWELL C MAXIMUM RACE INSERT 28.0 ROCKWELL C MINIMUM AND 37.0 ROCKWELL C MAXIMUM ROD END BODY |

| SURFACE TREATMENT | PASSIVATE OVERALL |

| SURFACE TREATMENT DOCUMENT AND CLASSIFICATION | ASTM A380 ASSN STD SINGLE TREATMENT RESPONSE OVERALL |

| STYLE DESIGNATOR | 6 BALL TYPE |

| OVERALL LENGTH | 1.8720 INCHES NOMINAL |

| BORE DIAMETER | 0.2495 INCHES MINIMUM AND 0.2500 INCHES MAXIMUM |

| OUTER MEMBER OUTSIDE DIAMETER | 0.8060 INCHES NOMINAL |

| BORE CENTER TO SHANK END DISTANCE | 1.4690 INCHES NOMINAL |

| OUTER MEMBER WIDTH | 0.3320 INCHES MINIMUM AND 0.3420 INCHES MAXIMUM |

| INNER MEMBER WIDTH | 0.4320 INCHES MINIMUM AND 0.4370 INCHES MAXIMUM |

| LUBRICATION MATERIAL | LUBRICANT, DRY FILM |

| LUBRICATION FEATURE | GROOVE AND PERFORATION INNER MEMBER GROOVE AND PERFORATION RACE INSERT |

| STATIC RADIAL LOAD RATING | 4675 POUNDS |

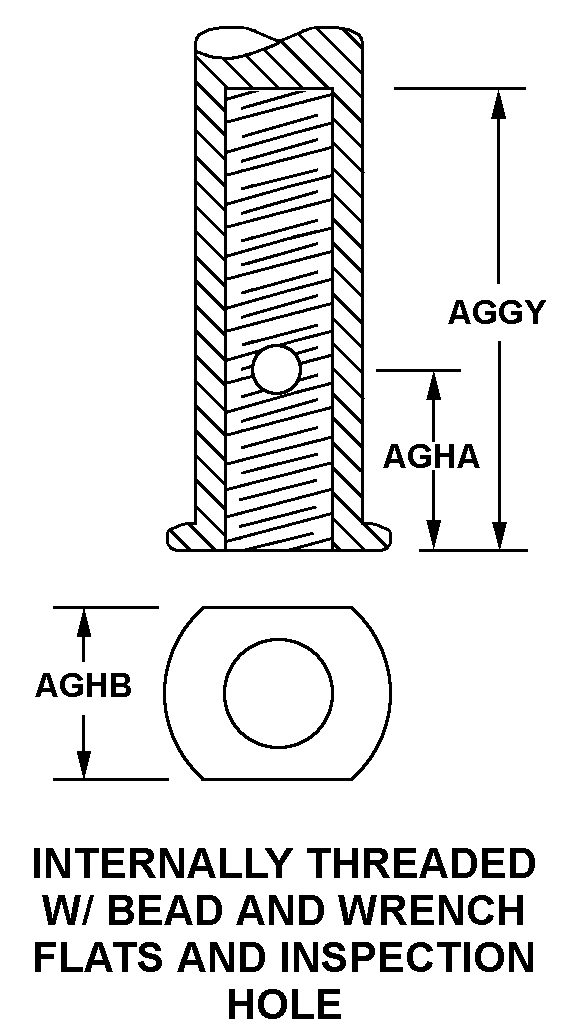

| SHANK STYLE | 5 INTERNALLY THREADED W/BEAD AND WRENCH FLATS AND INSPECTION HOLE |

| SHANK THREAD LENGTH | 0.7500 INCHES MINIMUM |

| INSPECTION HOLE CENTER TO END DISTANCE | 0.3750 INCHES NOMINAL |

| SHANK WIDTH ACROSS WRENCH FLATS | 0.4270 INCHES MINIMUM AND 0.4390 INCHES MAXIMUM |

| THREAD SERIES DESIGNATOR | UNJF |

| THREAD DIAMETER | 0.3125 INCHES NOMINAL |

| THREAD QUANTITY PER INCH | 24 |

| THREAD CLASS | 3B |

| THREAD DIRECTION | LEFT-HAND |

| SPECIAL FEATURES | DRY FILM LUBRICANT PER BAC 5814,FSCM 81205 TO THE BALL OD; LUBRICATION HOLES AND GROOVES OPTIONAL; 4 KEYWAYS IN SHANK END PER NAS559; PASSIVATE EXPOSED SURFACES ONLY |

| SPECIFICATION/STANDARD DATA | 81205-BACB10Z MANUFACTURERS STANDARD |

Restrictions/Controls & Freight Information | NSN 3120-01-203-4442

| Category | Code | Description |

|---|---|---|

| Shelf-Life Code: | 0 | Nondeteriorative |

| Hazardous Material Indicator Code | N | There is no data in the HMIS and the NSN is in an FSC not generally suspected of containing hazardous materials |

| Demilitarization Code: | A | Non-Munitions List Item/ Non-Strategic List Item - Demilitarization not required. |

| Controlled Inventory Item Code: | U | UNCLASSIFIED |

| Precious Metals Indicator Code: | A | Item does not contain precious metal |

| Criticality Code: | X | The item does not have a nuclear hardened feature or any other critical feature such as tolerance, fit restriction or application. |

| Category | Code | Description |

|---|---|---|

| NMF Description | 114850 | BEARING/BUSHING O/T BALL/ROLLER I/S |

| Less than car load rating | ||

| Less than truck load rating | Q | 70.0 |

| Water commodity Code | 742 | unknown |

| Originating Activity Code | KH | Defense Industrial Supply Center Philadelphia, PA 19111 |

| Air Dimension Code | A | Shipment is not a consolidation and does not exceed 72 inches in any dimension. |

| Air Commodity | V | Vehicles, machinery, shop and warehouse equipment and supplies, including special tools and equipment, ground servicing and special purpose vehicles, marine equipment and supplies, repair and maintenance parts for the above. |

| Air Special Handling | Z | No special handling required. |

| Special Handling Code | 9 | unknonwn |

| HAZMAT | ||

| Type of Cargo | Z | No special type of cargo code applicable |

Management | NSN 3120-01-203-4442

| Category | Code | Description |

|---|---|---|

| Budget Code | 9 | General Support DIV57X4921.070:Air Force decentrally managed expense items (ERRC XB3, XF-3) with a unit cost of less than $250,000 that are requisitioned/procured at base (retail) level from DLA, GSA, Army, Navy, Depot Maintenance Service, Air Force Industrial Fund (AFMC), local manufacture and commercial vendors. |

| Price Validation | N | The current standard price in Catalog Management Data (CMD) has not analyzed or coded for LP/LM.

|

| Fund Code | SF | Stock fund applicable to items managed for the Air Force by the respective Inventory Control Point. |

| Source of Supply | SMS | Defense Logistics Agency Enterprise Business Systems |

| Agency | DF | Department of the Air Force |

| Service Organization | F | U.S. Air Force |

| Reparability | N | Stock Fund (except Munitions) |

| Acquisition Advice Codes | D | DoD INTEGRATED MATERIEL-MANAGED, STOCKED, AND ISSUED # Issue, transfer, or shipment is not subject to specialized controls other than those imposed by the Integrated Materiel Manager/Service supply policy. 1. The item is centrally managed, stocked, and issued. 2. Requisitions must contain the fund citation required to acquire the item. Requisitions will be submitted in accordance with Integrated Materiel Manager(IMM)/Service requisitioning procedures. |

| Controlled Item Code | U | UNCLASSIFIED |

| Shelf Life Code | 0 | Nondeteriorative |

| Purchasing | QTY UOM |

1 EA : Each |